After visiting a ton of warehouses this year, I couldn’t help but notice two starkly contrasted types of warehouses.

Let’s call one warehouse type, Type A (for awesome). eEvery little detail seemed like it was taken into account. The floors were clean enough to eat off of and the pickers transitioned from zone to zone like they went through bootcamp.

The rest of the warehouses seemed to be part of another category. Let’s call it Type B (for bad?). In Type B warehouses, things seemed a bit more like…well, a war zone.

At first, I couldn’t figure out what exactly was different between these warehouses. It didn’t matter if a warehouse implemented a WMS or had a brand new lift truck. Both types had a plethora new tech and old that didn’t really correlate to how well they ran. I could not think of how to differentiate them, but it was really quite simple:

The Awesome warehouses could win wars.

Amateurs study tactics, while professionals study logistics.” – Napoleon

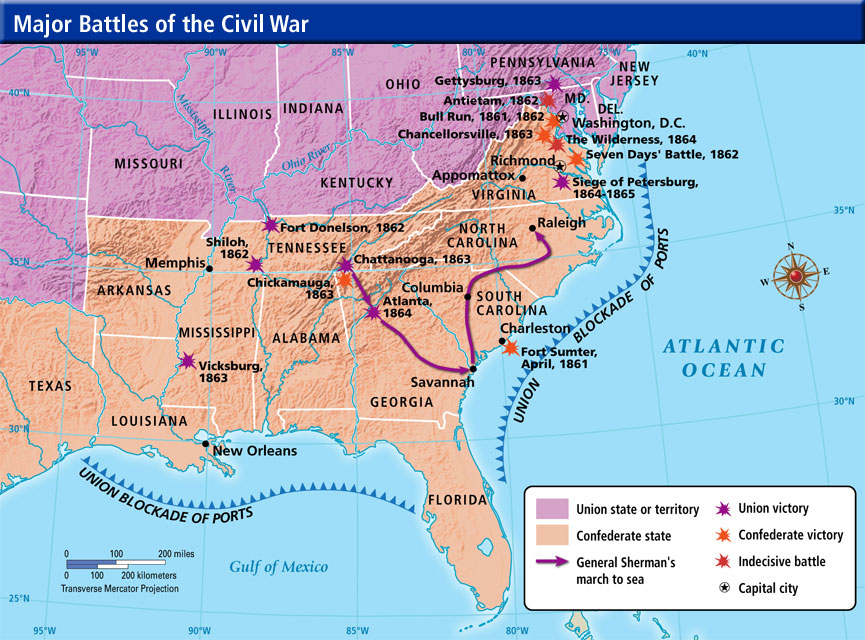

We could compare logistics in any war, but the most important one is the Civil War. It was the first war fought after the industrial revolution and started the traces of modern logistical methods still used today.

The convoy resupply system we still use in battles came from this war. If your warehouse can’t win the Civil War, it isn’t going to fare any better when we start throwing transcontinental movement into the mix.

Try to imagine president Lincoln placed you in charge of the Union’s logistics at the start of the war. You are going to have to make sure an entire army soon to be far away from home below the 48th parallel will have enough ammunition and food for the next four years. You ponder a bit and think about what technology you could invest in.

Have trains been invented yet? Luckily they have.

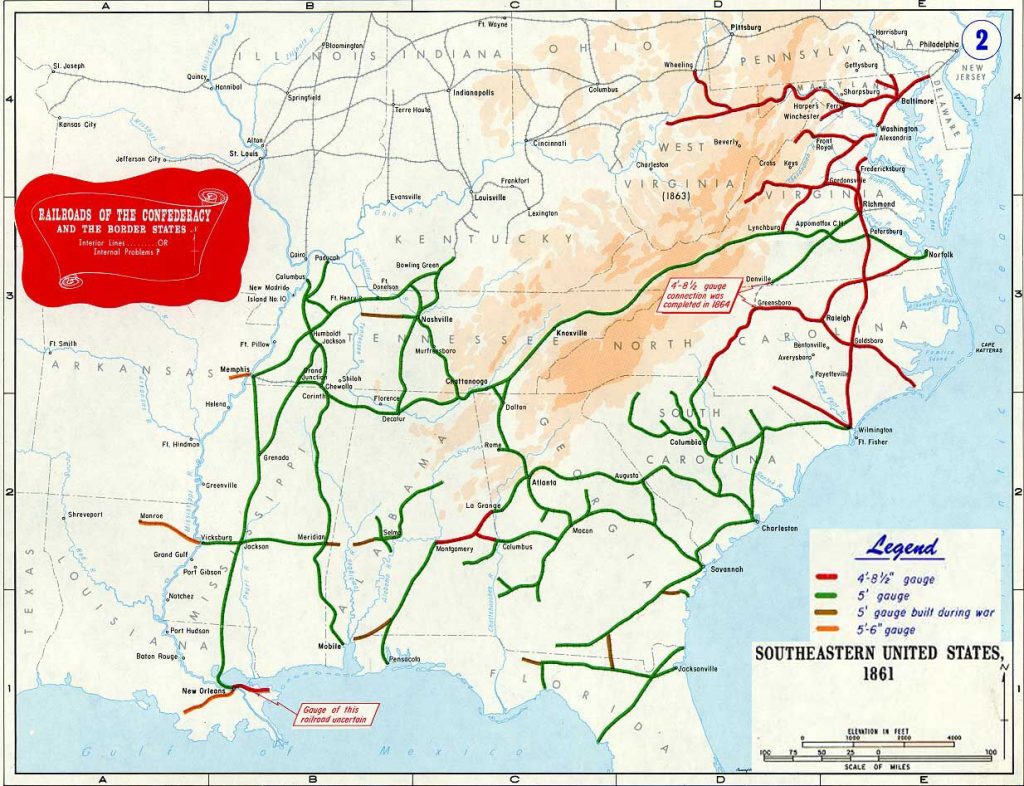

In fact, technology was a huge part of strategy for both sides. Nearly all battles were fought within a few miles of a railroad or a navigable water way.

Armies typically marched along the lines of a railroad due to speed and proximity of getting reinforcements, ammunition, or more food. Every 25th of the month, many Quartermaster Generals had the luxury of submitting supply requirements. If they were in an emergency, the supplies could be expected within a day.

Later in the war, without making any improvements to the railcar, they could be expected in four hours. How can that be? That’s 6 times the productivity without any additional investment in technology!

The secret was reliability. That meant no single points of failure, something could go wrong at any time and productivity would still have continued. Using the latest technology was an important tool for them, but definitely not the deciding factor.

Actually, the north and south had similar technology going into battle. There was no atomic bomb or stealth jet that turned the tide of war. Imagine how quickly the north would have won if they had one of those!

The Confederate army, on the other hand, ran into lots of trouble despite having railways too. Due to competing companies, the tracks they had to work with all had different gauges and did not connect. Every time they had to resupply, there were long delays where they had to move everything off the incoming car and transport it across town to the new one.

Technology without a reliable process was a complete waste of resources.

The Union figured this out early on in the war. In 1826, Earl Van Dorn saw General Grant relied heavily on resupplying through trains and raided their railroad junction depots. This turned out to be an extremely important supply depot for the Union and General Grant had to change something quick. Grant realized if that single depot could halt their entire army, they were better off being used as a backup for supplies than the main operation. He decided to focus on carrying the supplies using wagons.

Now, it is hard to put yourself in a pre-modern era but logistics life was much more complicated. for every horse-pulled wagon full of troops that rode into battle, it was said another wagon was needed just to carry the food for the horses. Wagons generally had 6 mules and each animal required up to 26 pounds of hay and grain a day. Forget medicine, soldier food, cooking materials like pans, and ammunition. It wasn’t exactly an upgrade from using a train.

But Grant kept trying, knowing he could reliably protect the wagons and if one or two got raided, the majority of his supplies were intact. Eventually, he started building on that to get a surplus of supplies without the railroads. They started marching with herded cattle, cooking the cattle as they got hungry. They saved more room in the wagons by foraging the earth for food. Passing through villages and farms didn’t hurt either. Even the Union hats were meant for carrying food.

They often stored vegetables and eggs in them as bags when foraging.

In the end, he figured out how to live mostly off the land. He only needed to store 5 days of supplies on the wagons at any time. Most of the weight they carried was now for bringing the very important ammunition. It was clearly slower than storing all their goods at a railroad injunction but Grant’s whole aim was 100% uptime.

Any raid or mishap was to be expected and nothing could stop their production. Historians say the sheer amount of raw materials the north decided the war. By the end, they were producing more materials than they could use. A couple times, they knew their supply lines were being destroyed but had such a surplus, it was a waste of troops to defend them. Railroads being torn, telegraph lines being cut, and bridges being destroyed. They could quickly rebuild anything that was needed.

President Lincoln himself cared deeply about logistics, knowing it decided the war as well.

“I can make brigadier generals, but I can’t make horses.” – Lincoln

The lesson is clear. Awesome warehouses know there is always going to be something going wrong. The question was – Could they continually operate at the same speed no matter what?

Meanwhile, Bad warehouses expect high-tech tools to solve all their problems without looking at the real inefficiencies in their operations. When these tools don’t provide relief, they too frequently end up just sitting in the corner collecting dust.

Speaking of which…

Fun Fact:

One Confederate city invested in creating a giant double-barreled cannon, believing it could turn the tide of the war.

The cannon was never even fired once to this day.